DuPont™ Cyrel® Solvent Workflow

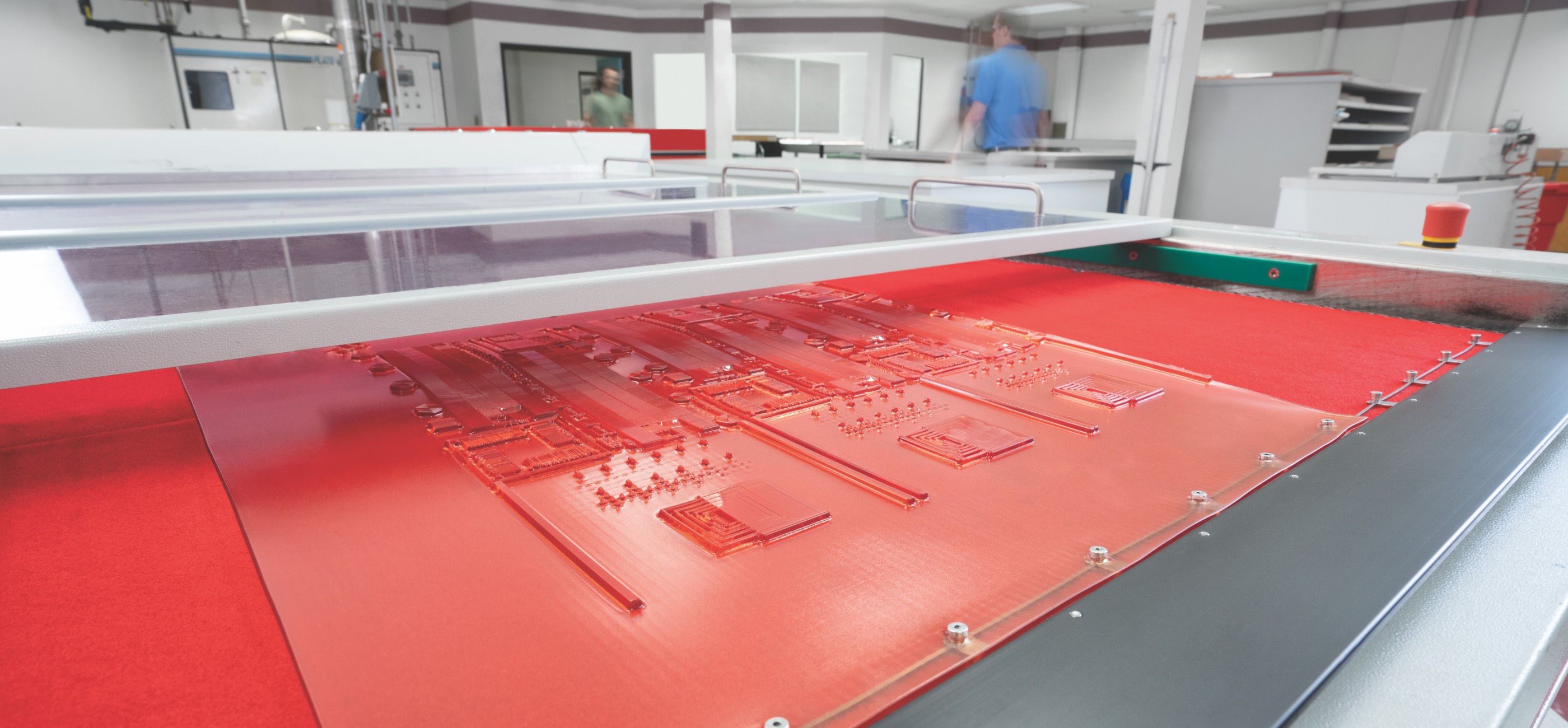

For those working in a solvent process environment, DuPont Packaging Graphics offers the Cyrel® solvent workflow, the most up-to-date line of processing equipment and the broadest array of plates in the industry today.

The DuPont™ Cyrel® solvent workflow consists of flexographic photopolymer plates and sleeves, as well as platemaking equipment and washout solutions. All are designed, and continuously improved, to provide the optimum balance of quality, productivity and speed.

Cyrel® Digital Workflow

Digital plate making is the most efficient way in modern flexography to produce the highest quality Flexo plates at the lowest cost. It has become the benchmark in our industry

DuPont™ Cyrel® invented the flexo computer-to-plate technology, developed the market and is continuously driving and implementing innovations based on it (ex.: Cyrel® Digital, Cyrel® FAST Digital)

This long term commitment and continuous innovations enable our customer to secure their investment and to participate in industry changes at the same time.

Cyrel® Analog Workflow

The very first plate introduced by Cyrel® used a graphic arts film negative to transfer the image information to the plate surface and wash-out solvent to remove the none printing plate areas. It was an Analog Plate.